Specially developed for high aspect ratio characteristics.

|  |  |

Descriptions

Specifically designed for high-density holes / double sided blind holes / high multilayer PCB plug holes process design, the vacuum value of up to 100pa within the vacuum operation, the use of high vacuum to achieve the conductive and non-conductive paste plug holes process, plug holes in a variety of materials, can be plugged with paste, silver paste, copper paste, conductive adhesive materials, and so on.

Features

★Can be produce the high aspect ratio panels( 70:1 ).

★High vacuum up to ≤ 100pa.

★Flexibility to realise: through holes, blind holes on one or both sides, back drilled holes, etc.on the same board surface.

★Ideal for small quantities and a wide range of gauges, no fixtures or air guides are required for hole plugging.

★The operating interface is automated, user-friendly and easy to operate.

Product Specifications

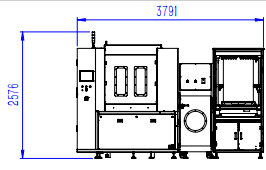

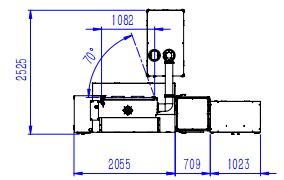

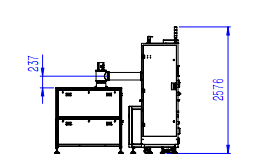

| Machine Size | 3791*2525*2576mm(one plugging and one ES unit) 6560*2525*2576mm(two plugging and one ES unit) | ||

| Vacuum | ≤30pa (Atmospheric pressure) | Panel thickness | 0.2-8.0mm |

| Panel Size | MAX:26 寸 *34 寸 (660*863mm) MIN:10 寸 *10 寸(250*250mm) | Aspect Ratio | Through hole: 70:1 (Max. after plating) Blind hole: 0.05mm 1:3 (Max. after plating) |

| Plugging method | Full plate plug holes (top to bottom) | Plugging speed | 2-80mm/sec(adjustable) |

| Plugging Hole Pressure | 0-6bar(adjustable) | Diameter of plugging holes | Through hole: 0.1-1.0mm (hole diameter after plating) Blind hole: 0.1-1.0mm (hole diameter after plating) |

| Noise (normal operation) | ≦ 75dB | Paste pressure | Cylinder push force: 0-6bar (adjustable) Pneumatic push force: 0-6bar (normal use does not exceed 3bar) |

| Plugging holes and plate edge spacing | Hole distance from plate edge ≥ 12mm | Operation Panel | Touchscreen operation |

| Protection Device | Safety light curtain, emergency stops | Failure rate | ≦ 1/400h(Failure time/equipment uptime) |

| Height of operating table | 1000±100mm | Number of paste recoveries | Not more than 4 times.Paste viscosity 500-700dpa.s |

| Plugging Production Requirements | ① Pre-treatment of incoming materials. ② Setting of pre-baking and time according to the TG number of the panel | Speed of scraper | 5-200mm/sec( adjustable) |

| Scraper pressure | 0-6bar(可調(diào) adjustable) | Paste Addition Method | Single paste clip replacement /Vacuum-LCS |

| Capacity | 20-70PNL/H(One plugging and one ES unit ) (Related to aspect ratio, plugging type, panel size, and vacuum, rejecting PTFE panel vs. ceramic panel )Same level or above | ||

Communal Requirement

| Electrical requirements | Electric:Three-phase five-wire 380V | Pressure of compressed air | ≧ 6.5bar |

| Power (output) | 14.65KW( One plugging and one ES unit) 28.55KW(Two plugging and one ES unit) | With pumping station exhaust volume | 450m3/h (One plugging and one ES unit) 900m3/h (Two plugging and one ES unit) (interface:φ200mm) |

| Compressed air consumption | 2.5m3/h ( One plugging and one ES unit) 5m3/h (Two plugging and one ES unit ) (interface:φ10mm) | Recommended space around machine | 800mm |

| Weight | 3200KG( One plugging and one ES unit) 6000KG( Two plugging and one ES unit) | Equipment Material | The material of the equipment is Q235+anti-corrosion treatment, the sheet metal is Q235+anti-corrosion treatment. |

| Equipment installation environment (temperature, humidity and dust-free requirements) | A. Environmental requirements: clean room, 100,000 level ↑ . B. Temperature requirement: 22±2℃ . C. Humidity requirements: 50±5% | ||