PSM-66 RIV-04 plug hole resin belongs to the halogen-free environmentally friendly products, the resin doesn't contain solvents and other harmful volatiles, can solve the problem of green oil blistering after lead-free tin spraying, this resin is suitable for selective resin plug hole process, resin plug holes out of the oil surface after the diffusion of a small, fast curing rate, to prevent the resin from entering the hole, can be a solution to the small spacing of plug holes bit problem. It has excellent high temperature resistance, no cracks, ultra-low diffusion, strong adhesion and chemical resistance.

Fields of application

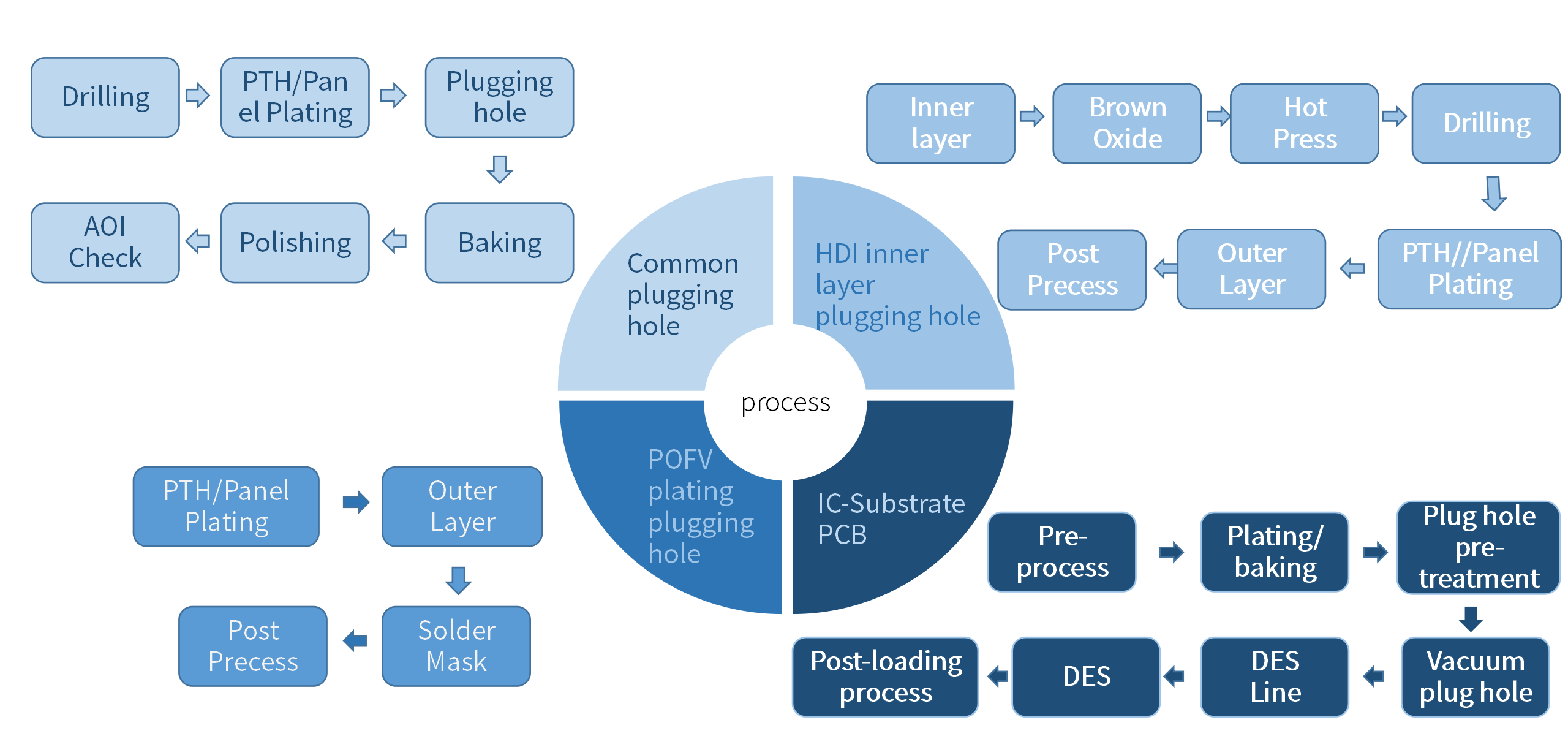

PSM-66 RIV-04 hole plugging resin is used for inner and outer layers, HDI, POFV, normal through holes + back drilled holes, and highly selective plugging difficult products. This product is mainly used for FR-4 sheets, medium and high TG products.

Illustration of plug holes for each type of plate

|

|

|

|

|

|

Technical Specifications

| NO. | Physical indicator | Test Methods | Reference Standard | Test results |

| 1 | Product Appearance | visual assessment | / | Yellowish white |

| 2 | Solid Content | Thermal Weightlessness | GB 1725-79 | 100% |

| 3 | Tg | TMA(℃) | IPC-TM-650 2.4.24 | 140-150 |

| 4 | CTE | TMA(<Tg)α1(ppm) | IPC-TM-650 2.4.24 | 40-50 |

| TMA(>Tg)α2(ppm) | IPC-TM-650 2.4.24 | 100-110 | ||

| 5 | Water Absorption | Gravimetric method(%) | IPC-TM-650 2.6.2.1 | <0.1 |

| 6 | Hardness | Pencil method | IPC-TM-650 2.4.27.2 | ≥6H |

| 7 | Insulation Resistance | Voltage method(Ω) | GB/T 10064-2006 | 1-3*1013 |

| 8 | Adhesion | Baige +3m tape method | IPC-TM-650 2.4.1 | 100/100 |

| 9 | Heat-proof material | Reflow soldering 260℃.60sec.3 cycle | IPC-TM-650 2.1.1.2 | Pass |

Thermal Stress 288℃.10sec.5 cycles | IPC-TM-650 2.6.8 | Pass | ||

| 10 | Chemical corrosion resistance | 10wt% NaOH 25℃*30min | IPC-TM-650 2.3.4.3 | Pass |

| 11 | TCT測(cè)試 | -50℃/30minó150℃/30min | IPC-TM-650 2.6.7.2 | Pass |

| 1000cycles | ||||

| 12 | Viscosity(25℃) | VISCOMETER TV-06 | - | 400-600 |